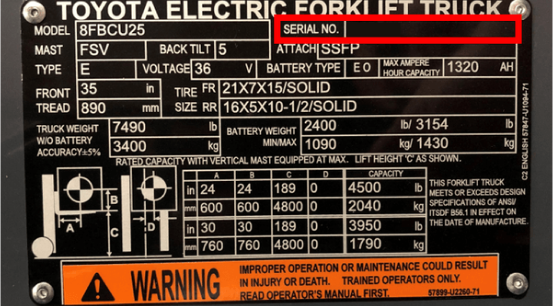

How to Find Your Equipment Model Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

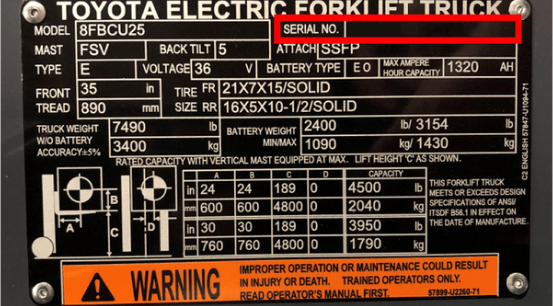

How to Find Your Equipment Serial Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer.

Please click below to sign in to your MyToyota account

Don't have an account?

Where would you like to go?

Powering Your Operation Forward Through a Toyota Power Study

In today’s fast-paced material handling environments, ensuring reliable and efficient power for lift trucks isn’t just helpful, it’s essential. That’s where a Toyota Power Study comes in. Let Toyota Energy Consultants be your guide in understanding your operation's energy consumption through a systematic, data-driven analysis specific to your fleet.

What is a Power Study and Why Does it Matter?

A power study is a structured assessment of your material handling equipment’s energy demands throughout typical operations. Conducted over a period of two to three weeks on your most frequently used lift trucks, these studies collect detailed metrics including:

- Run hours

- Shift schedules and break times

- Available charging opportunities

- State of battery charge

- Discharged and recharged amp hours

Whether your fleet uses electric or internal combustion trucks, a power study builds a comprehensive picture of how power flows through your operation and where improvements can be made. The goal of this detailed analysis is simple: ensure that your operation always has adequate power when and where it is needed without unnecessary downtime or wasted energy.

Learn from Toyota's Energy Solutions Consultant, Tanner Vogler, on how a Toyota power study can maximize your operation's energy efficiency.

Why Can the Wrong Combination of Energy Sources and Charging Equipment Be Problematic?

Using the wrong combination of energy sources and charging equipment can lead to increased downtime if they are not suited for the application. When the incorrect battery and charger are used, forklifts might not achieve the desired runtime, requiring operators to recharge the equipment more frequently.

Additionally, if a charger is not compatible with the incoming line voltage or breaker sizes, a new charger may be necessary, and there could be a need to frequently replace fuses and modules. It’s also crucial to choose a battery and charger that are approved by the forklift manufacturer to ensure they have undergone proper testing.

Is it Difficult For Companies to Choose Models That Are Best for Their Operation?

Toyota Material Handling aims to be a comprehensive solutions provider, offering a wide range of forklift models to choose from. With guidance from our Toyota Energy Consultants and an analysis of your power study results, we can recommend the best product options for your operation. This includes suggestions for battery and charger options as well. As your energy partner, we strive to make the process as easy and seamless as possible for you.

What Additional Services Do Toyota's Energy Consultants Provide?

Power studies and on-site consultations often provide valuable insights for customers, revealing opportunities for process enhancements. These enhancements can be straightforward, such as relocating the charging station to minimize travel time for operators, eliminating the need for battery changes to reduce downtime, or ensuring that the building has the appropriate infrastructure in place.

When you’re ready to take control of your energy usage, partner with Toyota.