How to Find Your Equipment Model Number

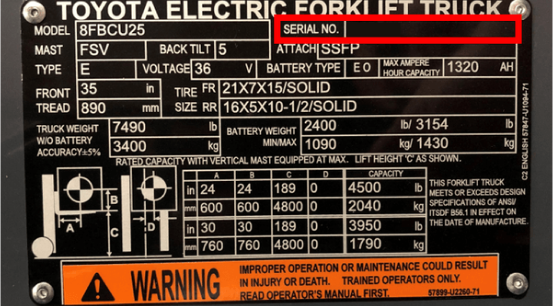

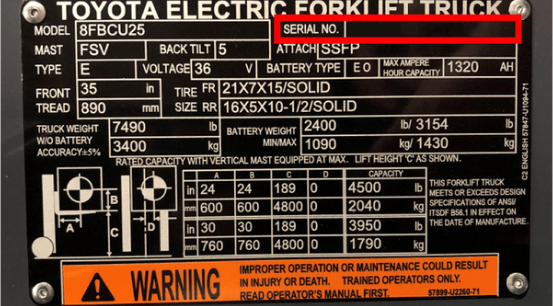

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

How to Find Your Equipment Serial Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer.

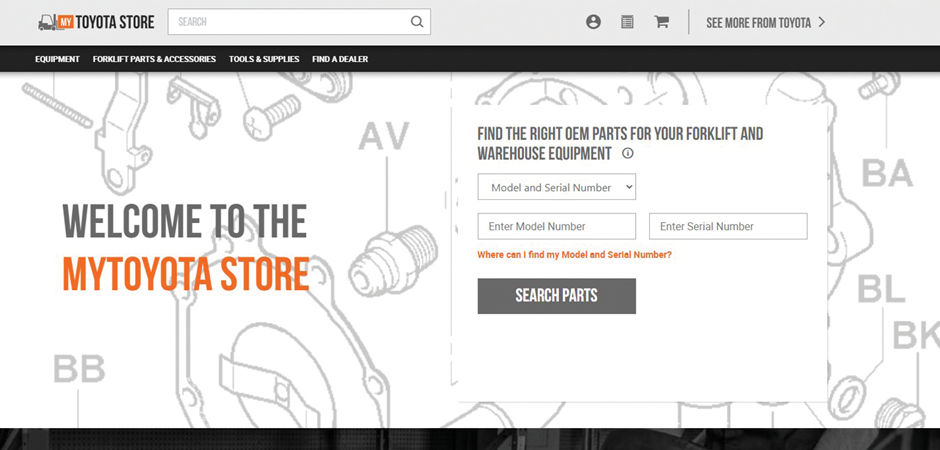

Please click below to sign in to your MyToyota account

Don't have an account?

Where would you like to go?

About Toyota

Toyota entered the North American forklift market over 50 years ago and has manufactured over 750,000 forklifts on U.S. soil. Toyota Material Handling, based in Columbus, IN, is a full-service manufacturer and distributor of high-quality forklifts, reach trucks, order pickers, pallet jacks, container handlers, scissor lifts, tow tractors, AGVs, and other automated material handling solutions. Built on a reputation of excellence, Toyota remains popular due to its quality, durability, reliability and overall value.

Total Solutions Provider

Toyota Material Handling, Inc. is committed to being your total material handling solutions provider. Forging strong relationships with automation technology companies and expanding its high-capacity line, Toyota can assist businesses in moving any material in your application – from port container to pallet to parcel. And as an innovator looking to provide every possible advantage to your business, Toyota’s energy research arm, Toyota Industrial Energy Solutions, is constantly working to provide the latest advancements in forklift battery and fueling technology – including making Toyota Material Handling the first U.S. manufacturer to establish UL certification for an integrated lithium-ion battery and forklift solution.

An Industry-Leading Dealer Network

The foundation of Toyota’s 360 Support promise, Toyota forklifts are backed by proven product support from an industry-leading network of dealers who offer a broad range of resources including: factory-trained service technicians, Toyota Genuine Parts, maintenance plans, safety solutions, and flexible financing packages through Toyota Commercial Finance. A North American network of 60+ authorized Toyota dealers and over 220 locations work together to offer industry-leading sales, service, and support to create partnerships for life

Company History

1956

The introduction of the Model LA 1-ton forklift, Toyota's first forklift model.

1967

Toyota establishes its first forklift dealership in the U.S. and sells its first forklift in the U.S.

1975

Toyota's first electric forklift, the 3-ton series, helped reduce air pollution.

1990

Toyota's first U.S. built forklift rolls off the line at the state-of-the art Toyota Manufacturing facility in Columbus, IN.

1991

The introduction of Toyota's new 5-Series electric forklift line with revolutionary SIT controller.

1995

The new 6-Series is introduced.

2000

Toyota launches revolutionary 7-Series internal combustion forklifts with world's first System of Active Stability (SAS).

2000

Toyota becomes the first major forklift manufacturer in the U.S. to offer AC technology.

2001

In 2001, Toyota acquired The Raymond Corporation, allowing TMHNA to leverage the unique strengths of both organizations.

2002

Toyota becomes the #1 lift truck company in America.

2005

Completion of National Customer Center.

2006

Toyota unveils the 8-Series line.

2010

Toyota unveiled its innovative new line of 8-Series 4-wheel AC electric lift trucks, available in 4,000 to 6,500 pound load capacities-including a new 5,500 pound model.

2015

TMHU celebrates its 25th anniversary of manufacturing forklifts in the United States.

2017

Toyota celebrates 50 years of forklift sales in North America.

2018

Toyota launches the MyToyota Store, paving the way for online equipment and parts sales.

2020

Toyota Material Handling launches 1-ton Core Electric models, the first forklifts fully designed and tested in Columbus, Indiana.

2020

Toyota Material Handling paid tribute to U.S. Veterans by building a camoflauge forklift that bears the symbols of major military branches and over 50 Associates who served.

2021

Toyota Material Handling completes largest project launch in company history with the introduction of 22 new electric models.

2022

Toyota Material Handling launched SEnS+ Smart Environment Sensor Plus™.

2023

Toyota Material Handling launched MyToyota, Toyota's comprehensive fleet management platform.

2024

Toyota Material Handling invests in a significant expansion of its headquarters. This new 295,000-square-foot manufacturing facility will be dedicated to producing electric products.

2024

Toyota Material Handling launched MyInsights, Toyota's standard telematics solution. As the only manufacturer to offer standard telematics, MyInsights, with a seamless integration through MyToyota, allows you to analyze material handling performance at your fingertips.

Assembled in the USA

Since 1990, Toyota has been proud to provide customers with high-quality products assembled at the award-winning Toyota Material Handling manufacturing facility based in Columbus, Indiana.

Corporate Sustainability

Toyota’s founding principle, the reason we exist, is to contribute to society while also remembering our core purpose in ‘Helping People Carry The Load.’ Toyota is passionate about serving our communities, giving our time, knowledge, and resources to support local organizations. We’re equally committed to operating our business in a sustainable way, with the goal of shaping a brighter future for the planet we call home. Together, we're choosing to build a brighter, greener, and more sustainable tomorrow.

Focused on Safety

Safety is Toyota’s top priority, and the creation of the world’s first System of Active Stability (SAS)™ is a testimony to that. Derived from automotive technology, SAS is able to electronically monitor forklift operations to help reduce the risk of accidents. When the SAS system detects instability, its advanced sensors simultaneously signal and engage the appropriate controller. The Active Control Rear Stabilizer, or the Active Mast Function Controller, adds stability and helps avoid accidents or injuries.