KEG1 O’Neal Video Case Study

(Read the video transcript here.)

Moving liquid products 24 hours a day can be very heavy work for any forklift. Some of these pallets weigh well over a ton each, but doubling that load with the same truck is much more than most other fork trucks can handle.

This is the KEG 1 O’Neal Distribution Center in Weatherford, Texas. The company is a regional beer distributor providing 135 brands of sudsy goodness from 67 different breweries and suppliers. The company’s customers include restaurants, bars, supermarkets, and convenience stores throughout 31 counties in North Central Texas. KEG 1 O’Neal owes its current size thanks to some timely acquisitions. Along with those purchases, the company acquired fork trucks from many different vendors including counterbalance trucks, walkie riders, and pallet jacks.

And just never were satisfied with the quality and the durability of the brands, and the capability of what we wanted to do and accomplish in our business. So we reached out to Toyota and bought our first one in 2006. Today, we’re at 110 pieces of Toyota equipment. We’ve made a whole conversion to Toyota handling equipment for our warehouse functions, inbound and outbound, our pallet building functions, preparing orders for delivery the following day, and then of course, electric pallet jacks where we deliver at retail with a 48-foot trailer.

KEG 1 O’Neal recently constructed this new facility with the goal of making better use of vertical space. While at floor stacks many of its faster moving brews, it also utilizes racking to store other brands.

We designed and built our building, and then reached out to Toyota to design and build the perfect forklift for our application.

KEG 1 was in a unique situation when they moved from their Mineral Wells facility to this Weatherford facility in the ability to build it however they want it to build it. One of their big things they wanted to do was take advantage of as much vertical space as possible. With the system built, they then had to find a piece of equipment that would meet those needs as well. Using the Toyota engineers and the Toyota special design process, we were able to develop a forklift that fit all those needs given the capacity they needed with the capacity retention, and again, get them as high as they needed to go to fit their system.

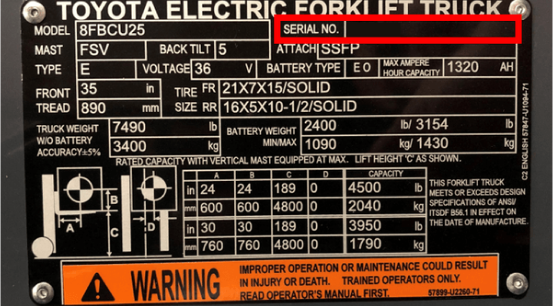

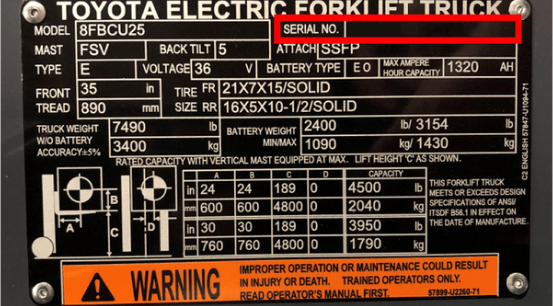

The forklift design that Toyota and Shoppas came up with is a counterbalance truck with a capacity to double handle pallets using the cascade single double pallet handler attachment. Moving to pallet simultaneously has been a tremendous time saver at KEG 1 O’Neal resulting in a huge jump in productivity.

It has cut our inbound load and unloading time in half and much more efficient because you’re removing two pallets or loading two pallets at once versus one, so brought a great efficiency to our inbound and outbound process. In result, saving time and money.

Another requirement that KEG 1 O’Neill had was being able to lift both pallet simultaneously for high storage either on floor stacks, or in the rack areas. That requires a truck that is extremely stable under heavy extended loads. The Toyota trucks that are deployed in this application have the capability of safely lifting one pallet, 276 inches from floor level, and two pallets, 156 inches high. The Toyota trucks are also very versatile and able to work outside in loading areas and in a cool room where kegs are kept at just the right temperature.

Else where in the building, orders are built using a fleet of Toyota electric pallet jacks. These versatile units can easily maneuver close to the cases needed for customer orders. Electric pallet jacks also wide along on the company’s trucks to make store deliveries. Shoppas continues to support these vehicles and all the fleet at KEG 1 O’Neal with fast service and parts deliveries within 24 hours.

We had their equipment on hand because we need it to make money. We need that equipment functioning 365 days a year, 24 hours a day. It’s important that our equipment stays up and stays running and functions properly. Shoppas has been a great partner, and helped us achieve that.