How to Find Your Equipment Model Number

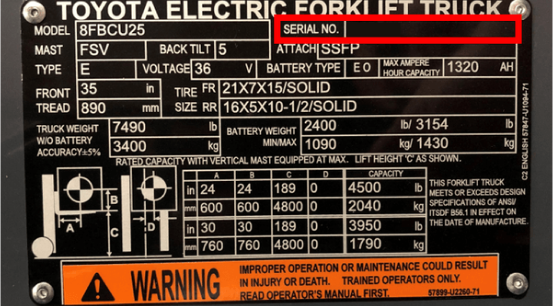

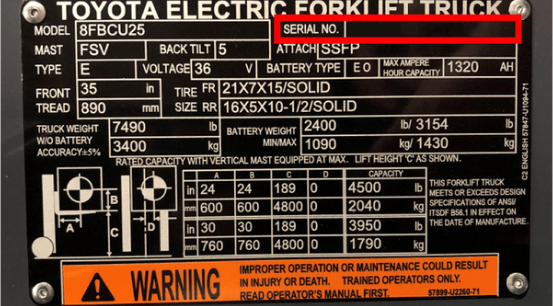

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

How to Find Your Equipment Serial Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer.

Please click below to sign in to your MyToyota account

Don't have an account?

Where would you like to go?

Calavo Growers Video Case Study

(Read the video transcript here.)

Calavo, we’re an avocado distributor outside of Dallas. This facility is 149,000 square feet. That includes ripe room, packing room, bagging machines. We do about 210 loads here on the average month. When we do have big events like the Super Bowl, that will jump up to about 350.

Shoppa’s is a dealer for Toyota material handling. I’m here to basically help them move their avocados. It’s almost like avocados are their own food group here in Texas.

They came and saw what we needed and was able to spec out a forklift to our needs. So we don’t have to interchange forklifts for certain areas of our warehouse. In our warehouse, you go anywhere from two to four high.

They also have drive in rack. And so we were able to have a forklift made that fits exactly in their drive in rack, that has a lowered height that goes in and out of their dock area, but yet it reaches the top, almost 20 feet in the air.

They made it easier for us to go in there and spec out the forklifts and be able to use every single one and every area of our facility.

So is this going to be full here in about a month?

Yeah. Right by Cinco de Mayo.

Their ripening rooms require things to be done in a timely manner. So if they have a piece of equipment that’s down, we’ve got to have a technician here very quickly to get that piece of equipment back up and running.

They’ll come and repair it, and if they can’t they’ll give us a rental and be able to stay on board with all our operations here. I have worked with other lifts. I mean, I’ve been in this industry since I was 20 years old. And for me Toyota has been better, less problematic, and we don’t have much issues. Which is very important. You can’t have issues and do your daily operations.

As we come up with solutions for customers. It’s really just simplifying their processes. It makes things easier, and also generally finds a cost savings as well.

At the end of the day, that avocado is going to be on somebody’s table, and that’s why I think it’s very important to take it serious. We’re loading trucks quicker. We’re receiving them quicker. We’re doing our production in our production area a lot smoother and there’s basically no downtime.