Megatrade Customer Story

Miles of Tiles

Beautiful tile products from Megatrade grace the floors and walls of distinctive homes. Toyota forklifts make sure they are handled with care.

If you shop for floor and wall tile at a Home Depot store anywhere in the Southeast, there’s a good chance that the tile came from Megatrade. Miami-based Megatrade is an importer and distributor of quality ceramic and porcelain tile from all over the world.

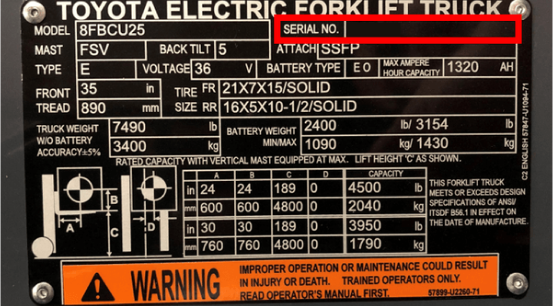

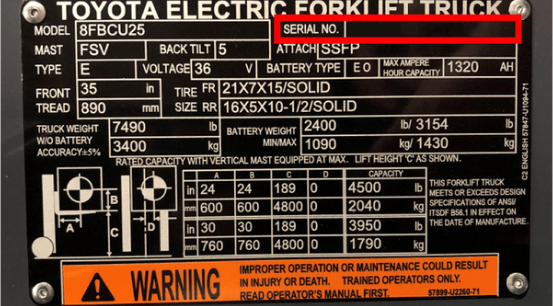

Each day, containers arrive from the Port of Miami and Port Everglades in Fort Lauderdale with pallets from Megatrade’s own manufacturing facilities in Venezuela. The distributor also receives imported tile from about 30 other suppliers in Italy, Spain, Ecuador, Colombia, Turkey, Brazil and China. It’s the job of Toyota forklifts to move the 1,000-plus different tile products from the containers to floor storage throughout the 110,000-square-foot facility in Doral, Florida. The fleet of eight counterbalanced forklifts easily handles loads of as much as 4,000 pounds. Often, two or three pallets are stacked upon each other and moved together.

Reliable Choice

Megatrade chose these Core 5,000-pound-capacity Toyota forklifts for their versatility, dependability and maneuverability. But it did not always use Toyota.

“When I came here 14 years ago, we had other equipment,” recalls Ruben Cruzalvarez, warehouse manager. “I had the experience of dealing with Toyota before, so I asked Toyota to come in and I introduced them to the company. Since then, and you’re talking about 14 years, we’ve been strictly a Toyota user.”

Cruzalvarez says that it is critical for Megatrade’s business that its trucks are able to operate consistently for 10 hours a day. He adds that the company cannot afford to have equipment go down for repair. “If you provide good maintenance, they will never quit on you. They run forever,” he says.

Products are stored in stacks within the warehouse. Overall, the facility can hold 11 million square feet of tile, floor-stacked as many as nine pallets high. The three-stage masts on the forklifts easily raise the pallets to reach the top of the stacks. Each truck is also equipped with side-shifter attachments to make it much easier to align the loads on the stacks.

“When we put one pallet right on top of the other, they have to stay aligned so that the weight is always on the pallet and on the tile. It is very important that when we are setting up one pallet on top of the other, they are aligned, and that’s why we use the side shifters,” says Cruzalvarez.

Working in Tight Spaces

All of the company’s sales are through distributors, as nothing is sold directly to the public. Picking is done directly from the stacks of pallets.

The stacks create narrow aisles in the building, but Toyota’s counterbalanced forklifts can easily turn, reverse, and change directions to navigate the tight confines. The see-through masts also provide excellent visibility to drivers even when carrying heavy loads. “The controls, the shifts and even the seats are comfortable. The drivers feel good with them and really like the Toyota forklifts,” adds Cruzalvarez.

Forklifts gather loads and take them to outbound docks for shipping. About 70 percent of the tiles for orders are selected as full pallets, while case-level picks make up the remaining 30 percent. On average, 10 to 15 outgoing trucks are loaded daily with the company’s tiles.

Since moving to the Toyota forklifts, Megatrade has seen how these trucks have the muscle and reliability to lift and move these very heavy loads day in and day out.

“We work them for eight solid hours, without stopping—only for a break and for lunchtime. They work to maximum capacity,” says Cruzalvarez. “If you give them maintenance, they will never, never let you down.”