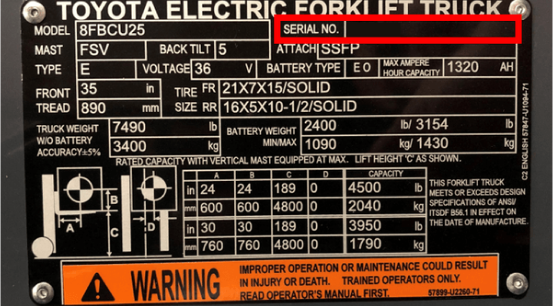

How to Find Your Equipment Model Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

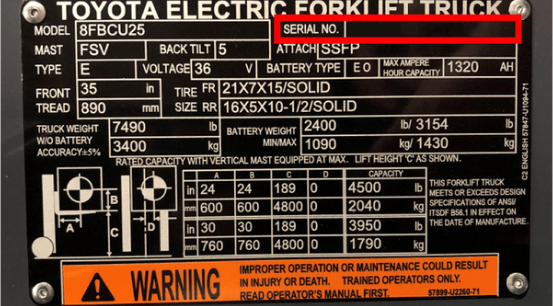

How to Find Your Equipment Serial Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer.

Please click below to sign in to your MyToyota account

Don't have an account?

Where would you like to go?

Which Forklift Energy Source is Best for Your Fleet Size?

There’s no “one-size-fits-all” option when it comes to powering forklift fleets — different sizes of operations, even within the same industry or environment, often require different energy solutions.

In fact, fleet size can be one of the most important factors when deciding which energy source is best. This is because the size of your fleet reveals a great deal about your operation’s needs in terms of cost, speed of fueling transition, and storage.

This guide may help guide your search for the best forklift energy option by helping you consider your fleet size as one of the determining factors in your decision. We explore internal combustion, electric, and lithium options.

Small Fleet

Operations with 1-2 forklifts have to weigh the higher, overall, the comparative initial cost of electric against savings in lifetime fuel efficiency. It can be cheaper to run a lead-acid battery-powered forklift than an internal combustion counterpart over their respective lifetimes.

Large Fleet

Operations with many forklifts have to consider whether the cost savings associated with electric remain high when faced with the need to buy additional lead-acid batteries. That need can lead to increased battery investment, storage space requirements, and maintenance time for watering and swapping.

In the long run, these costs can eat into overall efficiency savings, and internal combustion — or a transition to lithium-ion — might be better options.

Lithium-Ion Forklift Batteries and Fleet Size

Toyota's lithium-ion batteries don’t require traditional maintenance (e.g. watering), meaning your downtime and labor costs are reduced significantly when compared to lead-acid batteries. But, they are also more expensive than lead-acid batteries, meaning they’ll alter the outcome of your ROI analysis.

A more detailed analysis, such as a power study can help you definitively determine if the Toyota LiB battery is a good fit for your fleet size. To learn more about power studies and forklift energy solution options, reach out to your local, authorized Toyota Forklift dealer.