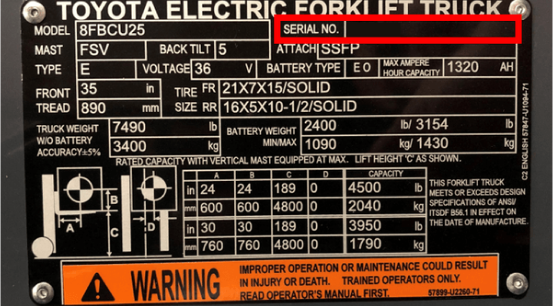

How to Find Your Equipment Model Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

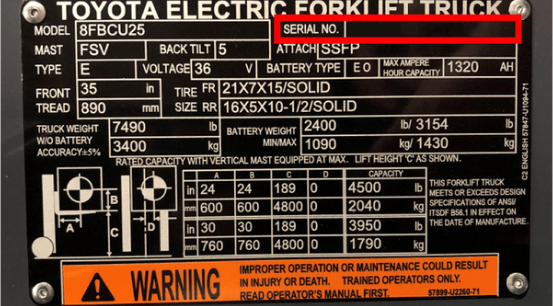

How to Find Your Equipment Serial Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer.

Please click below to sign in to your MyToyota account

Don't have an account?

Where would you like to go?

Exploring the Target Market for Lithium-Ion: Extreme Temperature Applications

There are quite a few applications where lithium-ion batteries make sense to power your forklifts – but some are garnering more attention than others.

The cold storage industry is the most obvious because of lithium’s ability to perform in a wide range of temperatures and environments.

In cold storage, lead acid batteries don’t perform as well because of condensation, and also because cold temperatures impede the chemical reaction in lead-acid batteries that releases electricity to power the forklift.

While this can also happen in lithium-ion batteries, the temperature of LiBs can be more easily regulated to combat this outcome. For example, unlike lead-acid batteries, LiBs can be manufactured with heaters installed to endure cold environments, and some LiBs feature active cooling elements to help in extreme heat applications.

Many lithium-ion batteries come with a rating of IP65 or greater, meaning the battery’s internal components are protected from water and condensation, as well as in temperatures as low as minus-31 degrees.

The main reason condensation isn’t an issue in lithium-ion batteries is the fact the cells are completely sealed and free from air. Lead-acid batteries are vented with air space in the cells, which allows condensation to form and impacts the chemical balance of the battery.

Lithium-ion cells operate most effectively in temperatures ranging from -4 degrees up to 140 degrees. But certain lithium chemistry combinations can expand that range – allowing LiBs to function better and last longer in extreme conditions.

A battery with a chemistry of lithium-iron phosphate or nickel cadmium, for example, performs better in cold applications than other types – effective in temperatures as low as -25 degrees. For high-temperature applications, nickel-metal hydride cells perform best – operating in temperatures up to 275 degrees.

If you use electric forklifts for applications where extreme temperatures are present, making the shift to lithium-ion technology may be the right solution for you.

To learn more, schedule an appointment with a Toyota consultant today to discuss what battery solution best suits your unique needs.