Understanding Different Pallet Material Types and Their Uses

Every day, warehouse operations, transportation companies, and other supply chain companies move a myriad of products all over the globe on pallets. Even though pallets are small, they play a critical role in the supply chain. The majority of the goods we consume spend at least some time on a pallet, somewhere in the world. This article will help you understand the different pallet material types and their uses.

Why Are Different Pallet Material Types Important in Transporting Goods?

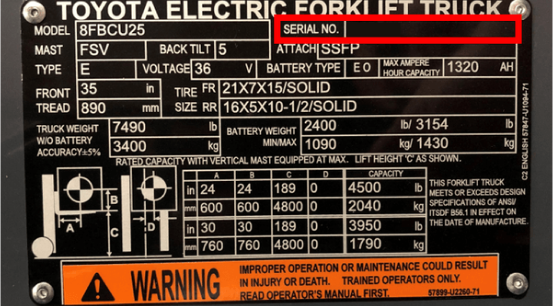

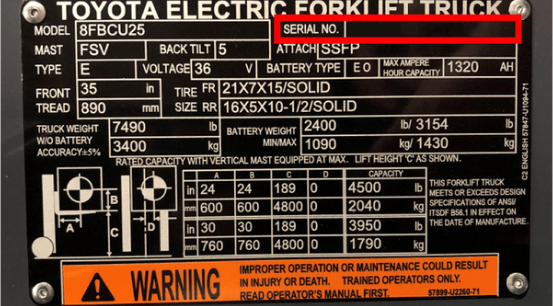

Without pallets, moving these vast amounts of goods from place to place is hard to imagine. Pallet (or unit) loads allow supply chain operators to move several products (referred to as “eaches” in the warehousing world) in one trip using material handling equipment, such as forklifts.

Pallets are designed specifically to be lifted by forks. While the configurations of most pallets are more or less the same, they are not all built out of the same materials. Different product loads and industries call for pallets that are made from different materials. Typically, pallets are made from wood, plastic, metal, or corrugated paper. It is important to note that certain industries have specific requirements for pallets and pallet composition and you should refer to the laws, standards, and regulations for your specific industry and application for more information about what kind of pallet is appropriate for use in your operation.

Let’s unpack the differences:

Wood Pallets

Wood composes the most common type of pallet, as it is one of the cheapest and most easily customizable options. Pallet manufacturers build these pallets from different types of wood at different costs and with varying strengths. Overall? A great, flexible option for general manufacturing operations.

There are some health and safety concerns that wood pallets present. Used wood pallets may carry bacteria, especially if the wood gets wet, so these pallets should not be used to transport food, beverages, or chemicals.

Plastic Pallets

Plastic pallets are a great option that can be used in just about any industry for any type of unit load, as long as the plastic can support the weight of the goods. They’re durable, easy to clean, and offer increased protection that helps ensure items won’t encounter damage during transportation.

Because of their durability, they don’t need to be discarded or replaced often. And even if they do, the plastic can be recycled.

Metal Pallets

Metal pallets present the strongest option, and they come in handy if you need to move extremely heavy loads. These pallets have the highest up-front cost, but they’re highly durable, can withstand extreme cold or heat, are easy to clean, and rarely need replacing. They’re typically made from either aluminum or steel, though the price will vary depending on which metal they’re made of.

Metal pallets are right at home when it comes to moving drums and barrels, airfreight, or outdoor storage.

Corrugated Paper Pallets

Manufacturer advancements in paper technology, such as special chemical coating, make it possible to make pallets out of corrugated paper. It may come as a surprise, but corrugated paper pallets provide the strength needed to accommodate heavy loads just as well as wood pallets. Plus, they are economical, environmentally friendly, and cleaner than wood pallets. And they’re just as easily customizable and recyclable.

They also won’t splinter like wood pallets might, and are relatively lightweight given their durability.