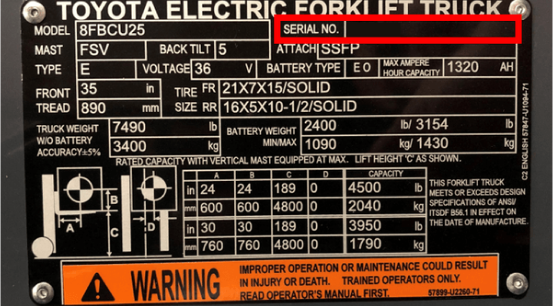

How to Find Your Equipment Model Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

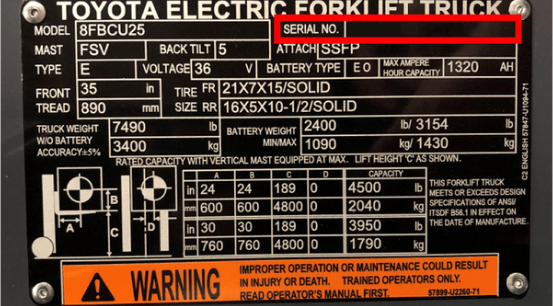

How to Find Your Equipment Serial Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer.

Please click below to sign in to your MyToyota account

Don't have an account?

Where would you like to go?

Our Commitment to the Environment Starts with a Promise to Our People

You may have heard us use this phrase before: monozukuri wa hitozukuri – making things is about making people. Providing our associates with the tools they need to do their jobs is a key part of this philosophy – but if we accomplish our goals at the expense of our environmental responsibility, then we aren’t promising our people the environmental health they deserve and need to do good work. Companies all over the world are growing increasingly focused on the environmental impact of their operations and on implementing sustainable business practices, and Toyota Industrial Equipment is no exception.

One of our major commitments was to avoid contributing to landfill waste, which threatens human health and the environment due to the release of several toxic gases from landfill biodegradation. To combat these harmful impacts, Toyota Industrial Equipment became a zero-landfill manufacturing facility in 2004 and has upheld this standard to this day.

How is this possible?

Each year, we divert 300 tons of materials an hour away from our facility in Columbus, Indiana, to Covanta Indianapolis, where it transferred to an energy-from-waste system. It’s an extra step that some companies may not think to take. But for us, it’s worth going the extra mile.

A slightly less drastic but still important measure was the installation of LED lights throughout our facility. This change means we’re using three tons fewer light bulbs annually. And what about all that paint that gives our forklifts their Toyota-orange pop? We’ve installed a solvent recycling unit and reduced paint waste by 50 percent.

We’ve also done our best to give back to local organizations such as Columbus, Indiana’s Parks and Recreation Department by donating trees that keep our community looking great while helping the environment.

It’s not about taking on every issue all at once – but about making the small changes that add up to larger positive impacts over time. You can join us in our commitment to our environment where our people live, work, and grow. Start by knowing what the environmental regulations are for your business and what you can do to go above and beyond those measures over time to make our environment safer and healthier for the people we rely on to get the job done.